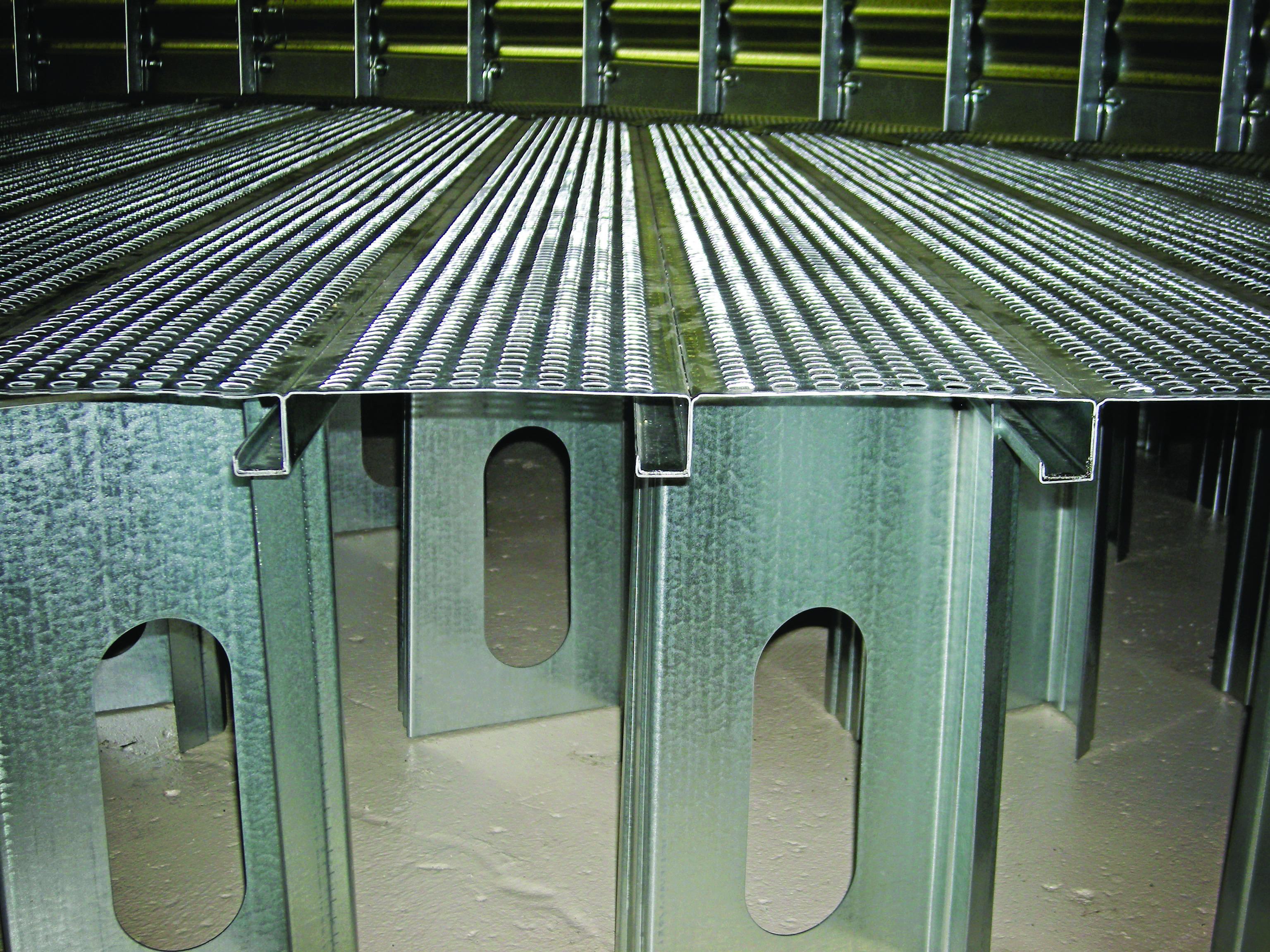

Bin Floors & Supports are designed to accommodate most drying or storage needs. Sukup Channel-Lok™ floor planks feature sturdy J-shaped, interlocking sides. Each plank is made of high-strength, galvanized steel and is cut to length with computerized accuracy. Sukup Heavy-Duty Perforated floors and SuperWave® Supports install easily over concrete tunnels for an efficient, low-cost aeration alternative.

Sukup manufactures Heavy-Duty Perforated, Hawk Cut®, and Channel-Lok™ Perforated bin floors. These bin floors are engineered for airflow and durability. They feature a design that promotes proper air circulation throughout the grain, a key factor in preventing spoilage and maintaining grain quality. The construction of these floors provides a stable and strong foundation for grain storage, supporting heavy loads while allowing airflow.

Sukup’s supports are built to enhance the strength and stability of the storage system. Sukup offers SuperWave® Supports, Z-Post, Super Supports™, and Flat Top Super Supports™. Sukup Superwave® Supports are one of the strongest supports on the market and work with all Sukup floor types. They feature a unique wave design that creates more surface area to support the floor planks, while simultaneously making the support more stable than other sheet metal supports. Super Supports™ and Flat Top Super Supports™ are typically recommended for drying bins. Sukup Super Supports™ can be used with most Sukup bin floors and provides excellent airflow, easy installation, and an extra strong design. Flat Top Super Supports™ are designed for use with Heavy-Duty Perforated floors. For details on compatible Sukup bin floors and supports, please visit the Bin Floors Brochure.

Together, Sukup’s Bin Floors & Supports provide a stable, durable, and well-aerated environment for stored grain. Sukup’s commitment to quality and innovation is represented in these products, making them a trusted choice for producers looking for reliable grain handling and storage solutions.

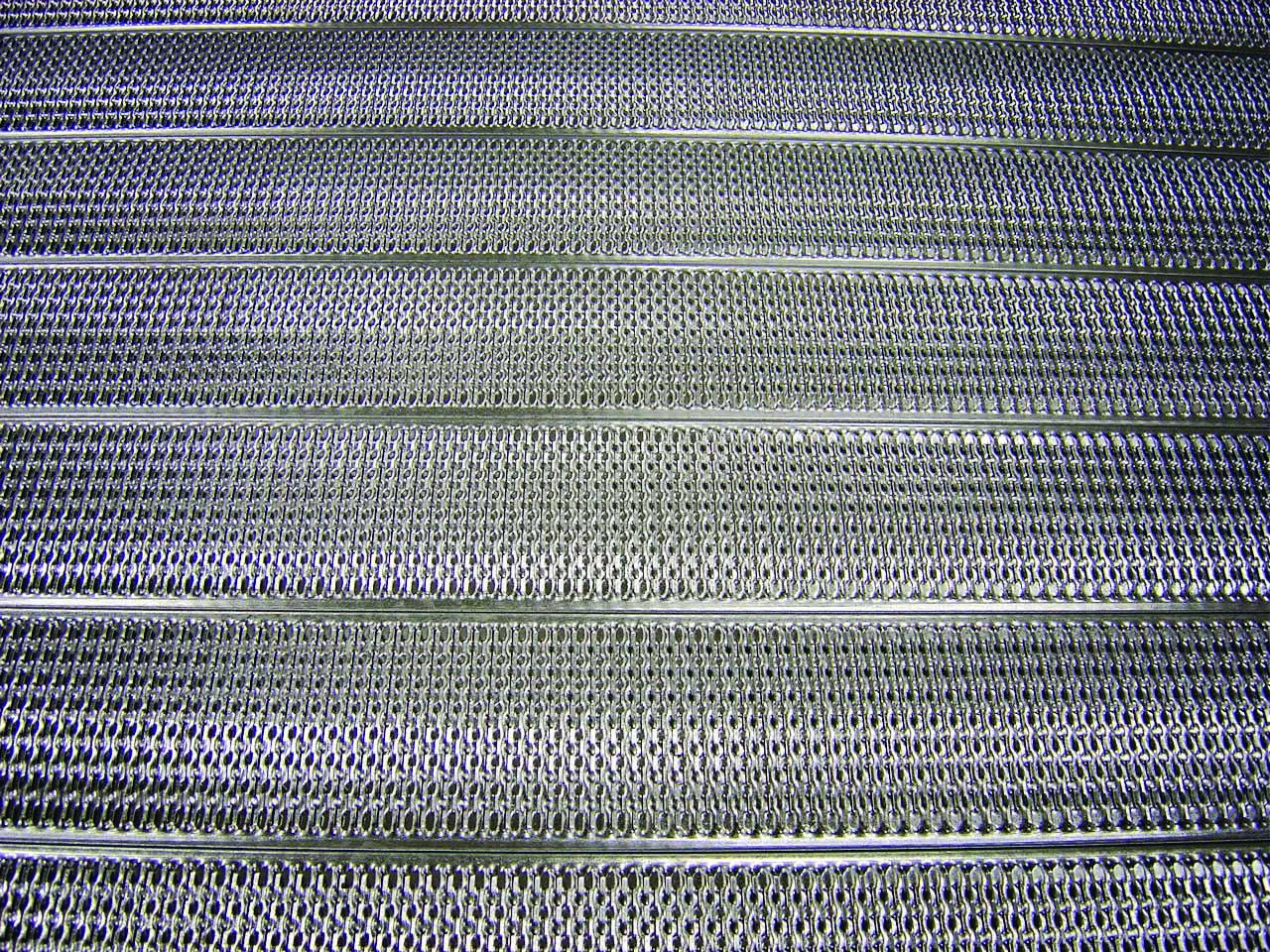

Sukup Hawk Cut® Bin Floors

- Twice as strong as other standard smooth bin floors

- Our exclusive process does not remove any steel in forming the large open area in the plank

- The high arch of the planks helps to increase strength

- Superior design makes Hawk CutTM planks idea for the demands of high grain depths

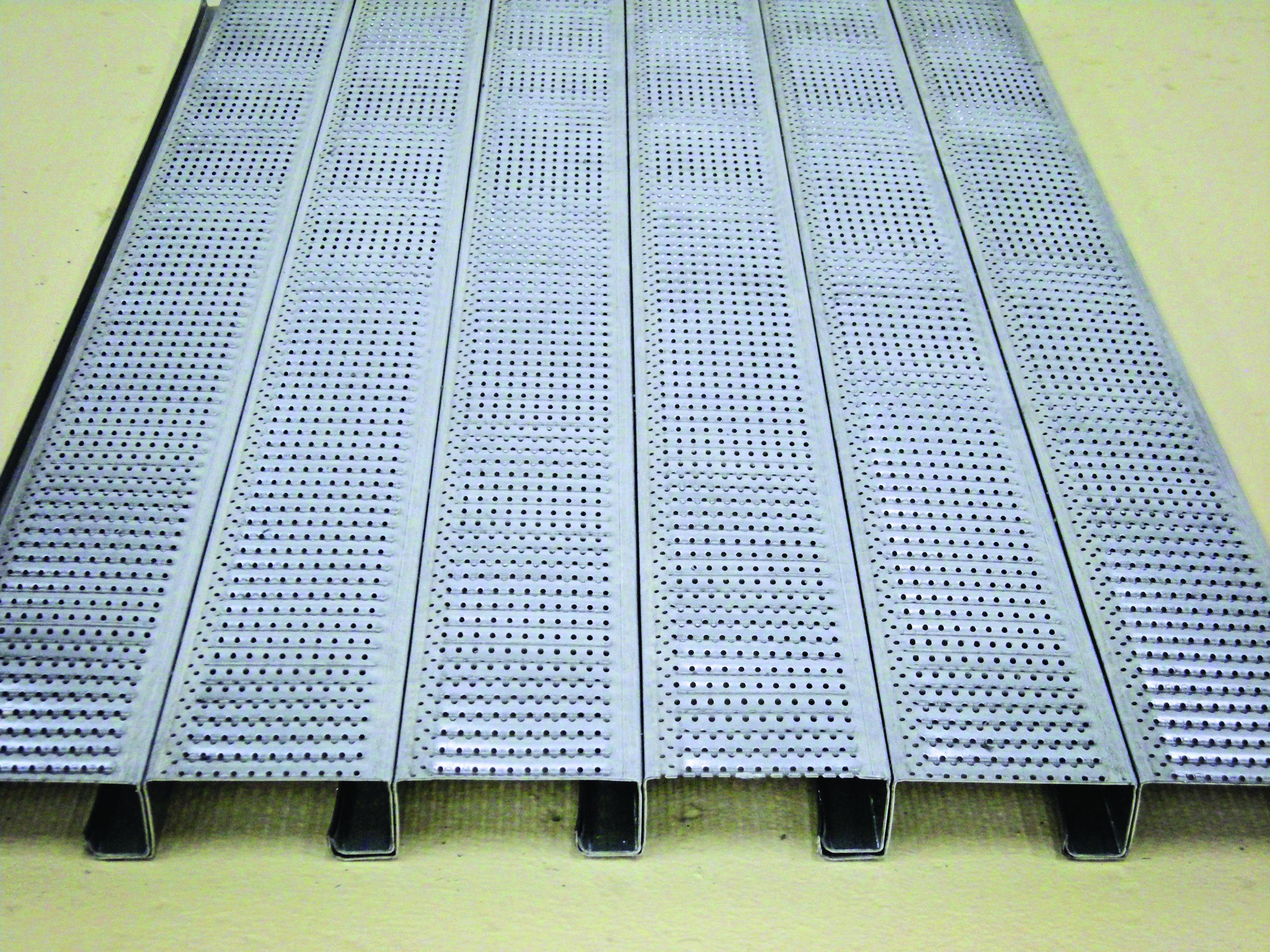

Heavy-Duty Perforated Flooring

- Designed for situations where perforated floors are preferred, but greater grain depths are desired

- Weight-bearing support every 3 ½”

- Roll form process creates 7" plank with intermediate channel

- Available in 0.0945” or 0.05” diameter holes

- Used with SuperWave™ (US Patent #8,297,016) Supports or Flat Top Super Supports™

Flashing

- Extra-strong Hawk Cut flashing gives 10” of coverage from the bin wall

- Width allows the flashing to fit easily around even small diameter bins

- 20 gauge – the heaviest flashing on the market

- Hi-back or low-back

- Hawk Cut flashing is available pre-punched for Sukup Airway® Tubes

- 0.05” diameter hole perforated flashing also available.

Z-Post Floor Supports

- Sukup Z-Post Supports cover a larger area, giving a wider, more solid base

- Z-Posts are fast and easy to install

- Notched sides and the self-tightening spring action lock the supports in place and help prevent shifting

- Available in 13-1/4” and 17” overall heights

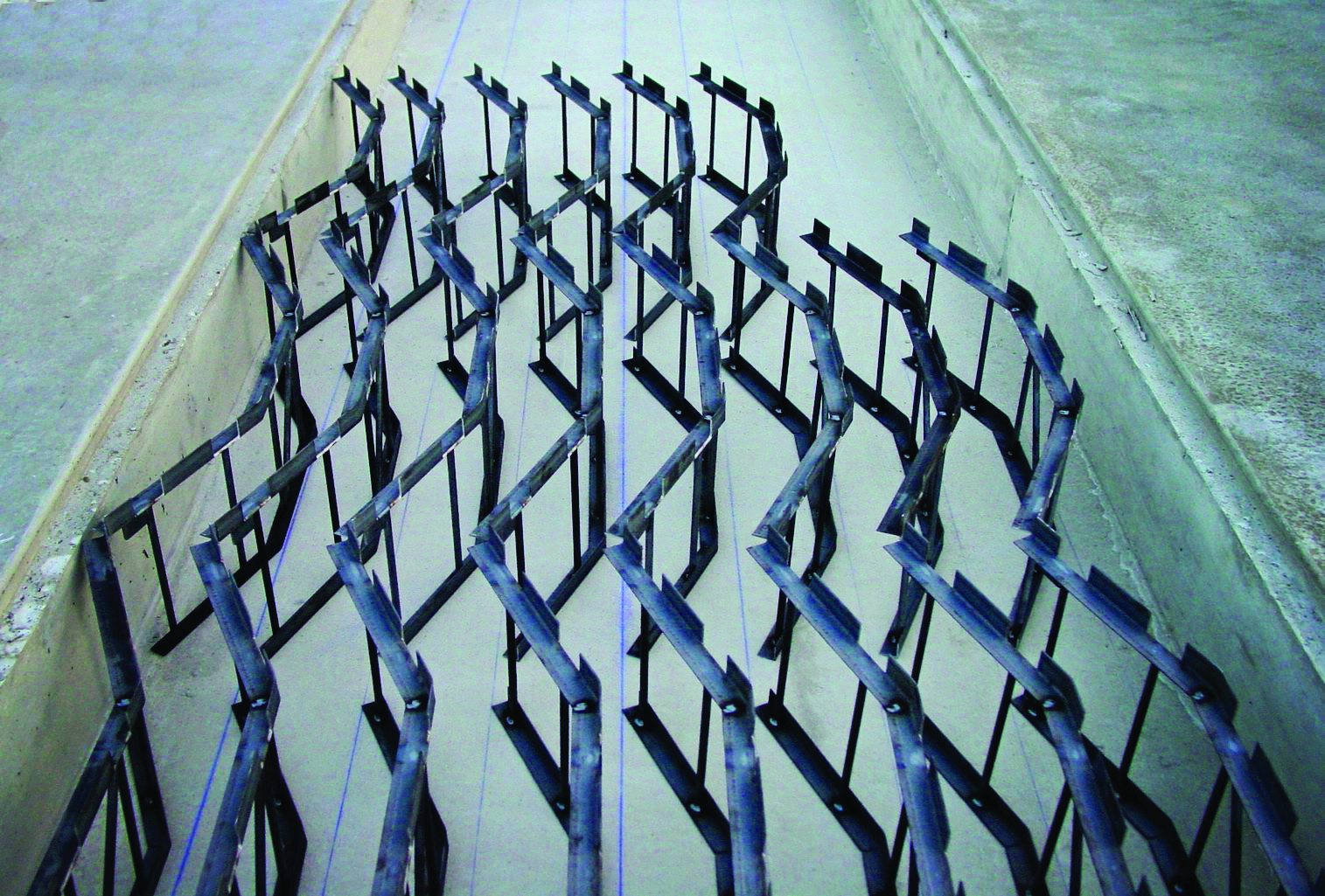

Super SupportsTM

- Welded-rod frame lets air flow freely throughout the bin plenum area

- Open design provides better heat distribution for more efficient drying

- Unique angle iron base provides stability

- Tabs provide support under the crown of the plank

- Available in 13-1/4" and 17" heights

Flat Top Super SupportsTM

- Used with Sukup Heavy-Duty Perforated Flooring

- All of the features of standard Super Supports™ without the tabs

Sukup SuperWave™ Supports

- Stamped metal supports work well with all Sukup floor planks, but they are particularly well-suited to our Heavy-Duty Perforated Floors

- Unique wave design provides excellent support and stability at an economical price

- Tabs provide support under the crown of the floor plank

- Can be used with the deepest grain depths

- U.S. Patent #8,297,016

Product Accessories

- Flashing may be pre-punched for Sukup Airway® Tubes

- Sukup Bin sidewall sheets may be pre-punched for flashing bolts

- Bridging supports required when floor support is narrower than width of the unload

Product Features

- Sukup Channel-Lok™ Floor Planks

- High-Strength, Galvanized Steel

- Corrugation Extends Completely Across the Width of Each Plank

Maumee, OH